Products

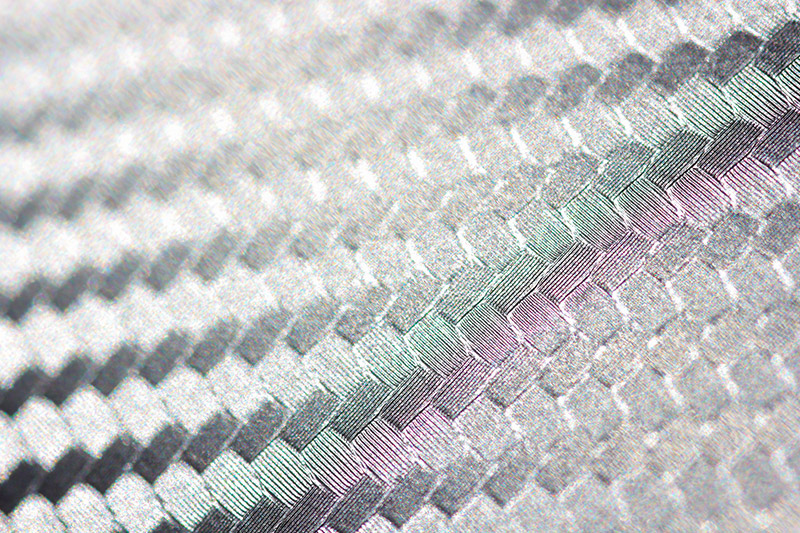

Aerospace Composite Materials and Auxiliary Materials

With the rapid development of the aerospace industry, the use of composite materials in aircraft has become an important indicator of the advanced nature of aerospace structures. Compared to single-component materials, composite materials have advantages such as high strength, high modulus, good fatigue resistance, low thermal expansion coefficient, good high-temperature performance, strong shock absorption capability, and strong designability.

In the aerospace field, approximately 80% of composite materials require a significant amount of auxiliary materials and composite mold materials during the manufacturing process. These materials include vacuum bag films, release films, pressure-sensitive tapes, peel plies, breather fabrics, sealing tapes, hoses, and silicone rubber. These materials must meet high requirements in terms of high-temperature resistance, high-pressure resistance, and manufacturing processes.

Aerospace Metal Materials

Aircraft requires metal materials that can withstand the pressure and stress caused by high altitude, extreme high temperatures, and adverse weather conditions. We offer a variety of high-performance aerospace metal materials, including aluminum, aluminum alloys, bronze, and titanium, serving aircraft manufacturers, large assembly companies, aerospace machine shops, and maintenance and repair facilities.

We closely collaborate with globally renowned aerospace metal material suppliers. As qualified suppliers for Airbus and Boeing, their products are manufactured and processed according to the most stringent aviation standards. Simultaneously, we work to enhance our customers' supply chains, reduce inventory, and free up operating capital, striving to be the preferred supplier capable of meeting all of our customers' comprehensive aerospace material needs.

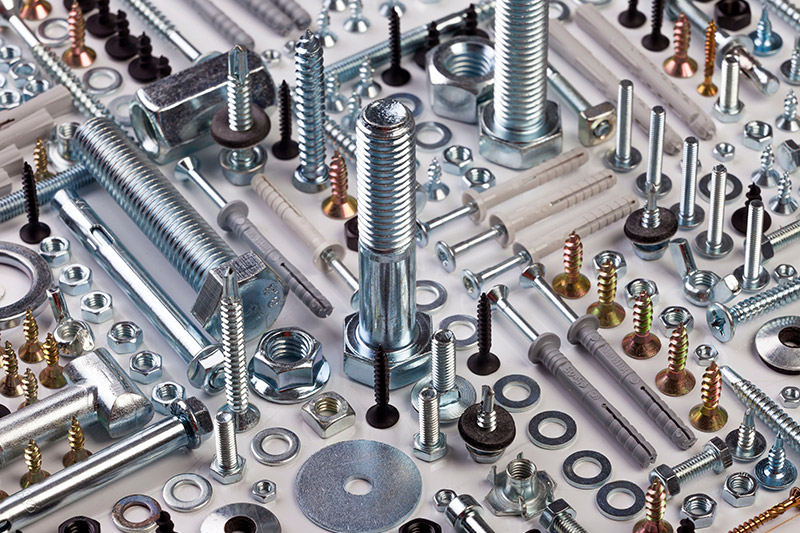

Aerospace Standard Parts and Other Components

The role of fasteners is to connect thousands of components in an aircraft, forming a cohesive unit. A large commercial aircraft may require over three million fasteners. Unlike ordinary industrial fasteners, aerospace fasteners have extremely high requirements in terms of shear strength, tensile strength, fatigue strength, application temperature, corrosion resistance, and are typically made from materials such as aluminum alloys, titanium alloys, nickel-based alloys, and others.

With our global network of company channels, we maintain close partnerships with leading aerospace component manufacturers and platform suppliers worldwide. The range of components we can supply covers virtually all the standards and specifications for civil aviation, ensuring that our customers' needs can be met with rapid response and precision.

Finished Parts

Blitztark also offer components or elements that have undergone the entire manufacturing and assembly process and are ready for use in commercial aircrafts. These parts have been meticulously designed, engineered, and crafted to meet stringent standards of quality, precision, and safety required for commercial aerospace applications.